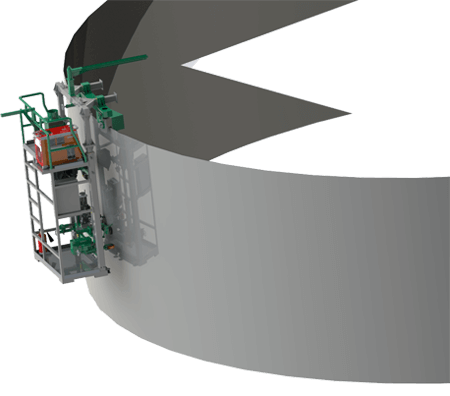

Tank Welding Systems

Askaynak tank automation systems provide rapid and precise welding for the tanks / storages at once.

Askaynak tank automation systems have ability to weld till 8mm thickness sheet metal of minimum 8000mm diamater of storages.

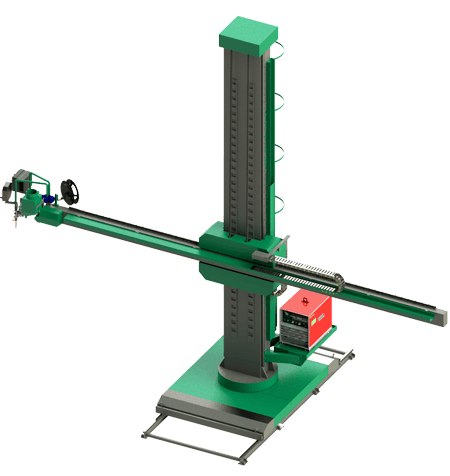

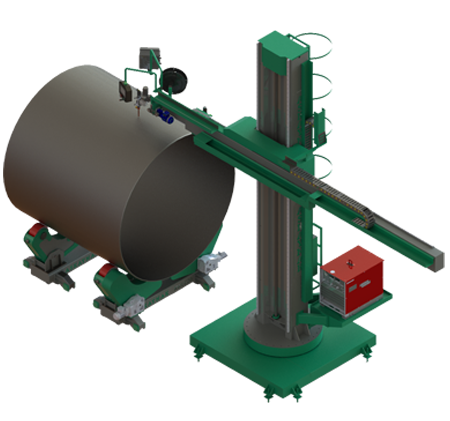

Conventional Column-Boom Systems

Askaynak Column–Boom Systems enable to weld the cyclindrical materials by help of rotators and positioners, and gives great advantage of labor cost.

System has linear sliders which provide precise welding quality without vibration.

Telescopic Column-Boom Systems

Askaynak Telescopic Column-Boom Systemsare designed for welding of tall materials like wind towers.

Telescopic columnboom systems consists of parts that operate within nested structure with the same logic in telescopic cranes.

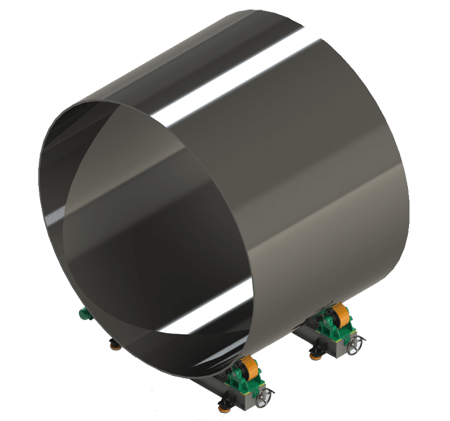

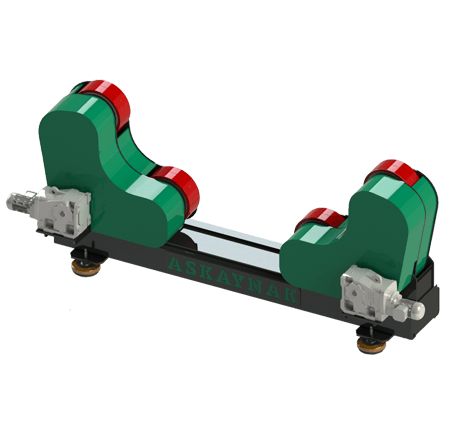

Conventional Rotators

Askaynak conventional rotators can be used for materials that their diameters do not differ too much.

Rotators enable to rotate the circular materials without extra adjustment. This system provides excellent rotation without slippage by its 4-drive wheels.

Self-Adjusting Rotators

Askaynak self aligning rotator systems ensure rotation of different diameter of materials by aligning itself automatically.

Rotators enable to rotate the circular materials without extra adjustment.

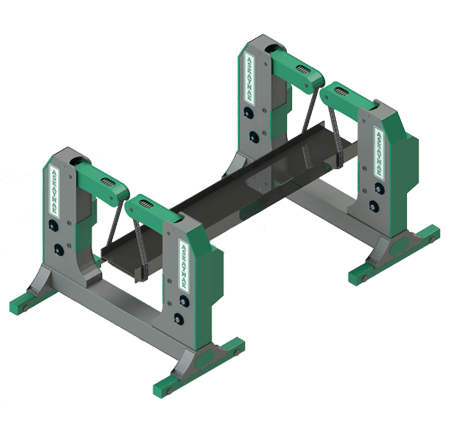

Chain Type Rotators

Askaynak chain type rotators ensure easy rotation of metarials like H, I profiles to have proper welding position by its unique design.

Askaynak chain type rotators increase time saving since external Crane is not used to change position of welding materials.